PRODUCTS

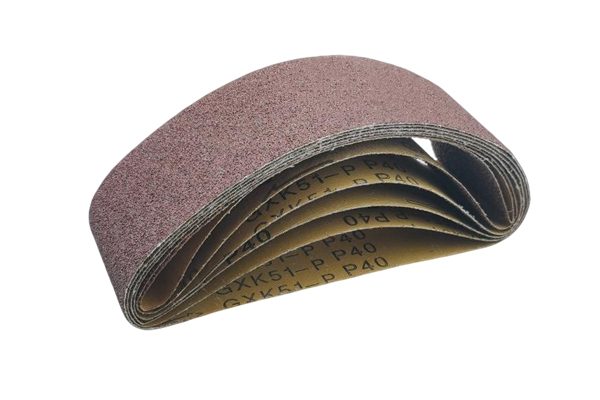

Sanding Belt

- Product ID:

- Size: 100mm

- Material Science: Aluminum Oxide

- INQUIRY

High-quality abrasives—including aluminum oxide, silicon carbide, and ceramic variants—boost cutting efficiency by 20 to 30%. Its uniform heat dissipation design lowers the risk of workpiece burning while prolonging the sanding belt’s service life.

Anti-clogging coating technology minimizes debris adhesion, extending the belt’s lifespan by over 40% compared to traditional sanding belts. The high-strength substrate also enhances tear resistance by 50%.

It caters to the needs of multiple industries, such as woodworking, metalworking, composite materials processing, and automotive surface treatment. Customizable specifications—covering width, particle size, and joint process—meet precision machining requirements.

It complies with EU REACH and RoHS standards, ensuring no heavy metal pollution. It also features low noise and low dust emissions, adhering to OSHA/NIOSH standards.

Its wear resistance is 3 to 5 times higher than that of ordinary aluminum oxide sanding belts, giving it strong competitiveness in the high-end European and American markets. Additionally, it reduces grinding vibration, making it suitable for high-precision processing and a top choice in the German and Japanese markets.

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China