How long do sanding sponges last?

How long do sanding sponges last?

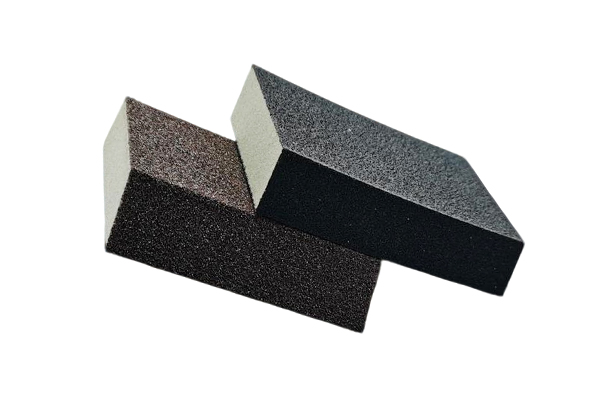

Material and grit size are primary determinants. Sponges with coarse grit (40-80) wear faster due to aggressive material removal, especially on hard surfaces like metal or hardwood.

Fine-grit sponges (240+) last longer for light sanding and polishing. Foam density matters too: high-density sponges retain shape and abrasive particles better, outlasting low-density alternatives that deform easily.

Usage conditions also play a vital role. Sanding hard, rough materials (e.g., concrete, rusted metal) accelerates wear compared to soft surfaces like drywall or plastic.

Wet sanding can shorten lifespan if the sponge isn’t water-resistant, as moisture weakens abrasive bonding. Excessive pressure during use clogs pores and wears down grit faster, while proper cleaning (tapping out debris) extends service life.

General guidelines: For hobbyists or occasional DIY projects, a sanding sponge may last 2-5 tasks. Professional users tackling daily heavy work might replace them every 3-7 days. Signs to replace include worn grit (no sanding action), persistent clogging, or deformed foam that fails to maintain even pressure.

To prolong lifespan, match grit to the task, avoid overpressing, clean debris regularly, and store sponges in a dry place.

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China