Non-woven / Scouring Pad

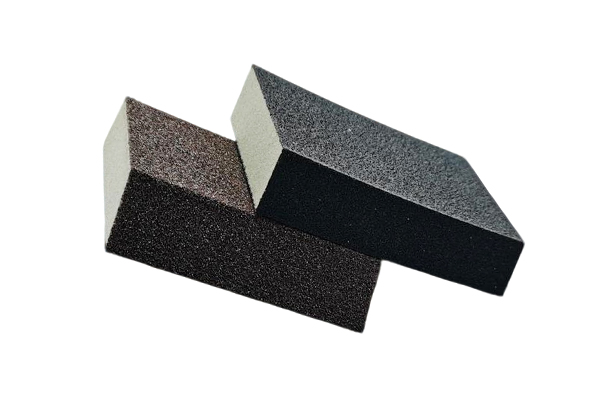

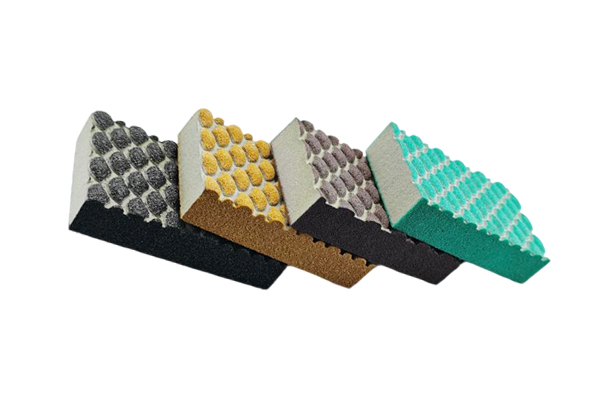

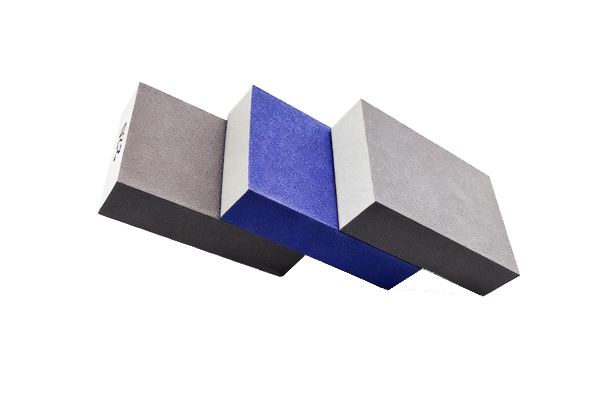

Sanding Sponge Blocks

- Product ID:

- Size: customized sizes

- Material Science: Plastics , EVA sponge

- INQUIRY

Industrial sanding sponge blocks are primarily used for the sanding of surfaces such as metal, wood, and composite materials, excelling particularly in handling curved surfaces, edges, and complex geometric workpieces (e.g., automotive parts, mold repair, furniture processing).

The core selling point lies in their “soft-hard combination” design: the sponge base provides elastic pressure adaptation, avoiding excessive wear caused by the rigidity of traditional sandpaper. The high-adhesion abrasive surface layer (such as silicon carbide or aluminum oxide) ensures efficient cutting while supporting both dry and wet applications. Compared to conventional sandpaper, it offers improved grip comfort, significantly reduces operator fatigue, and meets the demands of high-intensity assembly line work.

Compared to traditional sandpaper, it increases unit grinding efficiency by over 50% and is reusable (with an average lifespan of 8–10 uses), leading to a total cost savings of approximately 40%. In contrast to high-end electric sanding tools, its lightweight and zero-energy-consumption features provide greater procurement flexibility in small and medium-sized factory settings, creating a “substantive cost advantage.”

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China