PRODUCTS

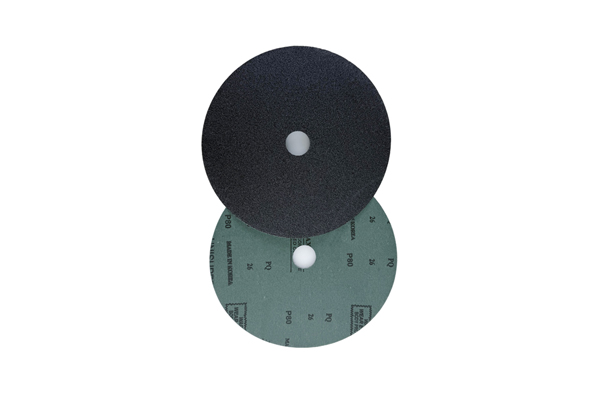

Silicon Carbide Fiber Disc

- Product ID:

- Size: 4‘’ / 4.5‘’ / 5‘’ / 6‘’ / 7‘’

- Material Science: Silicon Carbide

- INQUIRY

Silicon Carbide (SiC) has a extremly good hardness profile, making it suitable for processing hard materials it can maintain stability at temperatures above 1200°C, reducing the wear of grinding discs at high temperatures. Its lifespan is 3-5 times longer than that of standard aluminum oxide grinding discs, thereby reducing the frequency of replacement. The cutting efficiency is improved by more than 30%, reducing working time.

It has a wide range of applications, suitable for metal processing, automotive manufacturing, aerospace, electronic components, glass ceramics, etc. It can be used for various processes such as rough grinding, fine grinding, and polishing.

The use of adhesive optimization technology reduces dust pollution (complies with EPA standards in Europe and America). The high-strength fiber backing plate reduces the risk of breakage during high-speed operations.

Low single-use cost: although the unit price may be slightly higher, the long lifespan dilutes the overall cost (saving 20-30% compared to traditional grinding discs).

Certified by EU CE, US OSHA, and ISO 9001, it meets the market access requirements of Europe and America. German TÜV wear resistance test data leads: under the same working conditions.

Advantages of production in China: labor costs are 30% of those in Europe and America, , and the overall production cost is 15-20% lower. The repurchase rate of industrial customers reaches 85% (industry average is about 70%).

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China