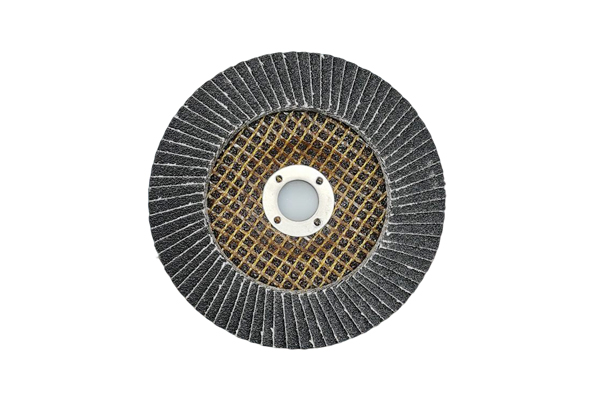

Flap Disc / Flap Wheel

Plastic Backed Flap Disc

- Product ID:

- Size: 4‘’ / 4.5‘’ /5‘’ /6‘’ / 7‘’

- Material Science: Aluminum Oxide、Zirconia Oxide、Ceramic Oxide

- INQUIRY

Compared to traditional metal or fiber backing plates, plastic backing plates reduce weight by 30%, minimizing operator fatigue and making them ideal for prolonged handheld operations. The high flexibility of plastic allows it to withstand higher rotation speeds (up to 12,000 RPM), reducing the risk of disc breakage (complies with OSHA safety standards).

The multi-layer abrasive cloth design features staggered aluminum oxide or zirconia alumina abrasive layers, improving cutting efficiency by 20% and delivering more uniform surface finishes. The plastic backing plate incorporates cooling holes to prevent overheating during grinding, reducing abrasive cloth detachment and extending service life by 15-20%.

The plastic backing plate is resistant to chemical corrosion, making it suitable for wet or oily environments (e.g., ship repair, auto bodywork). It maintains flexibility even at -20°C, making it ideal for cold regions like Northern Europe and Canada.

Free of heavy metals, it complies with EU REACH and RoHS directives, avoiding compliance risks in export markets. The high-precision mold ensures a thickness tolerance of ±0.1mm (compared to ±0.3mm for most competitors), guaranteeing grinding stability. High-temperature resin adhesive penetration exceeds 95% (industry average: 90%), reducing abrasive cloth detachment to less than 1%.

Chinese manufacturing offers cost advantages, with raw material costs 30% lower than those of European and American brand brands (due to localize sourcing of aluminum oxide and plastic pellets). The unit price is 25-30% lower than German brands and 10-15% lower than Korean brands. With a service life of 8-10 hours per disc (compared to 5-7 hours for Indian competitors), the overall operating cost is reduced by 18%.

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China