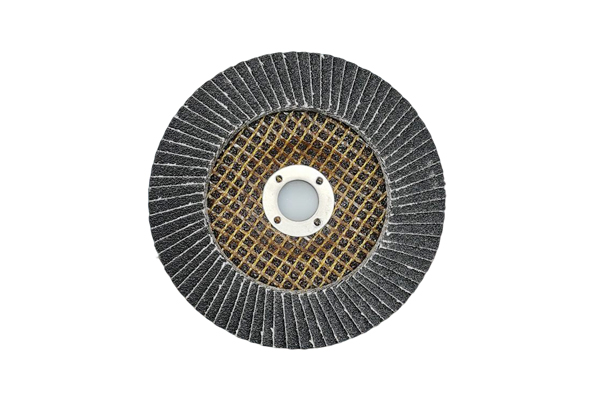

Flap Disc / Flap Wheel

Flap Wheel

- Product ID:

- Size: 4‘’ / 4.5‘’ /5‘’ /6‘’ / 7‘’

- Material Science: Aluminum Oxide

- INQUIRY

Combining the advantages of grinding wheels and sandpaper, it is suitable for integrated operations such as rough grinding, fine grinding, and polishing, reducing the frequency of tool changes (saving 20%-30% of labor time). Reusable (low replacement frequency), with 30%-40% less dust emission than traditional grinding wheels, compliant with EU REACH and RoHS standards.

Multi-layer abrasive cloth overlay design automatically exposes new abrasive material as it wears, extending lifespan 3-5 times longer than traditional grinding discs. The backing plate dissipates heat quickly, reducing the risk of material scorching.

Compatible with various abrasives (aluminum oxide, silicon carbide, ceramic, zirconia alumina), suitable for processing metals (stainless steel, aluminum alloy), wood, composites, etc.

The flexible abrasive cloth design reduces equipment recoil force, complying with OSHA and CE safety standards, minimizing operator fatigue and workplace injury risks. A wide grit range (40-120 grit for rough grinding, 120-320 grit for fine grinding) makes it ideal for weld seam grinding, deburring, surface polishing, and other applications.

Certified with ISO 9001, CE, ANSI, and other standards, meeting EU and US market entry requirements, supporting OEM/ODM customization. Special specifications (such as ultra-thin flap discs, high-temperature-resistant coatings) can be customized to meet heavy industry needs like automotive manufacturing and shipbuilding.

Chinese manufacturers can achieve 15%-20% lower raw material costs (aluminum oxide, resin) through bulk purchasing, 30%-40% lower electricity costs compared to Europe and the US, and 30%-40% lower labor costs through automated production lines. Prices are 25%-35% lower than those of European or American brands (e.g., 3M, Klingspor), with mid-range products offering comparable performance and outstanding cost-effectiveness.

Integrated grinding reduces tool change frequency, improving overall efficiency by 25%-35% and lowering labor time costs.

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China