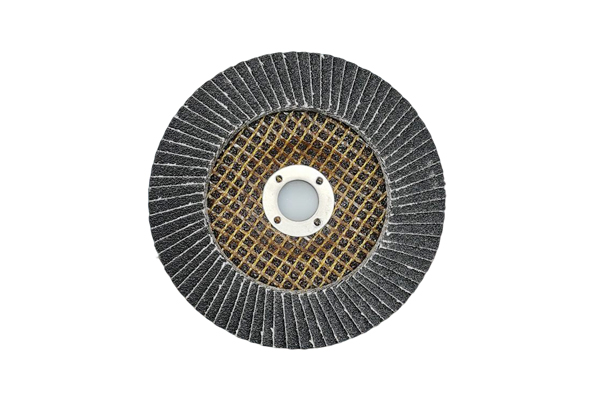

Flap Disc / Flap Wheel

Flap Wheel with Shank

- Product ID:

- Size: 15mm、20mm、25mm、30mm、35mm、40mm、50mm、60mm、75mm、80mm、100mm

- Material Science: Aluminum Oxide

- INQUIRY

The fan like pattern of the abrasive sheets allows the wheel to have some flexibility and contour around work pieces with ease. These flapper wheels are able to grind along curves and are especially helpful when used to grind, blend or polish in tight spaces such as the inside or the outside of tubes.

1.The multi-layer abrasive cloth sheet overlay design provides uniform cutting force, suitable for fine grinding, deburring, and weld cleaning of metals (stainless steel, aluminum alloy), wood, and plastic.

2.Compared to fixed grinding wheels, flexible flaps can conform to curved surfaces, reducing excessive material wear and improving efficiency by approximately 20-30%.

3.The lifespan of these wheels can be up-to 2-3 times that of an ordinary grinding wheel, with some products featuring anti-clogging coatings (such as ceramic adhesives) to minimize dust emission, complying with the European EN 12413 safety standard.

4.The cost of raw materials for Chinese manufacturers is 25-40% lower than in Europe and America, with labor costs only 1/5 to 1/3. The export price of Chinese produced flap wheels with shanks can be 30-50% lower than that of European and American manufactured brands, with procurement volumes from emerging markets increasing by 15% annually (2023 customs data).

5.Compliant with EU REACH regulations (free of phenol and formaldehyde), these wheels have the ability to enter high-end automotive/aerospace supply chains.

6.We support OEM/ODM production, and can offer customized specifications.

PRODUCTS

News

Contact Us

Contact: Kamel Abrasives

Phone: +86 13663827325

Whatsapp: +86 13663827325

E-mail: sales@kamel.com.cn

Add: High Technology Area, Zhengzhou, Henan, China